Product Description

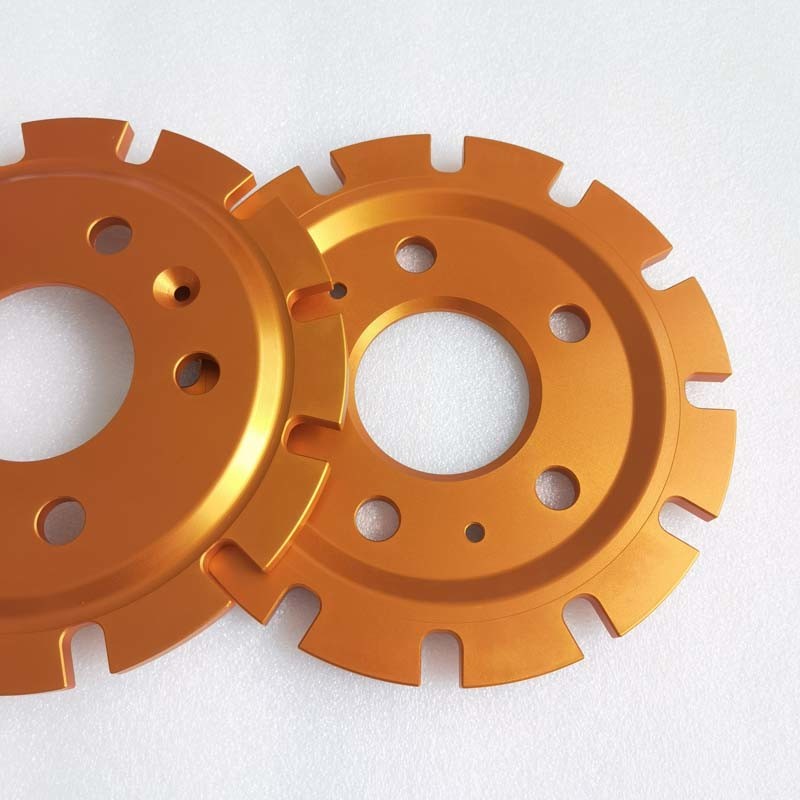

Brake Disc Bell Orange Aluminum Center Cap Fit 330*28mm Brake Disc

Brake DiscBell is the part connecting the modified caliper and the car. Each set of alloy Center cap bracket is customized according to the model, caliper model and disc data.

The center cap and disc body are generally made of different materials, with different thermal expansion coefficients. In addition, the heating conditions are also different. For example, the thermal expansion coefficient of aluminum alloy is very high, while carbon fiber shrinks by heating. Without a mechanism, they can move relatively, the braking effect is greatly reduced, and even the disc may be directly stepped on and cracked.

Brake disc bell bracket is a very important accessory in the brake system, which is lost by a thousand miles. If the processing accuracy is not enough, there will be shaking and other phenomena during braking, resulting in poor braking effect, eccentric wear of brake pads and other problems.

Brake precautions

The more common problem in the braking system is the abnormal brake noise, which has been encountered by many car owners. Generally, the abnormal braking sound is that when the vehicle steps on the brake while driving, the braking system will make a sharp 'metal friction sound', which often occurs after rain.

If this happens, it is mostly due to the thinning of the brake pad, the grinding of the brake disc by the back plate, the hardness of the brake pad and the presence of foreign matters in the brake pad, which will lead to abnormal noise. Therefore, when there is abnormal braking noise, first check the thickness of the brake pad. If the thickness is OK, slamming on the brake with a few feet may alleviate the problem of abnormal noise.

The modification steps of brake are as follows:

1, although the brake power provided by cast iron brake discs may not be powered by the alloy material brake disc produced by the awesome factories in Europe, the heat dissipation effect is slightly inferior to that of the perforated brake disc.

2. When choosing the brake, be sure to inform the store of the displacement or hole spacing of your car. Because the hole pitch of my 1.6L naturally aspirated model is 5x105, but if it is a 1.6T turbocharged model, the hole pitch becomes 5x115.

3. After the original brake disc was removed, it was compared with the brake disc with a diameter of 330 mm. It was found that the original 280 mm brake disc was only so small.

4. Some rust will be left on the surface of the brake joint, so the joint shall be polished with a grinding wheel at the first time after removing the original brake disc. If it is installed directly without grinding, the brake will shake.

5. After the joint grinding is completed, the bridge code and brake disc are installed. There is a small bottle like eyedrops in the box. When asked, I knew it was thread oil to prevent looseness.

6. Use an Allen wrench to install the caliper on the bridge yard. It is recommended to replace a set of wheel hub products with smaller et value while replacing the brake.

7. After the steel pipe is installed, there is both brake oil and air in the brake pipeline. If you drive away directly, the air bubble in the pipeline will be compressed when you step on the brake, and the brake is equivalent to failure.

8. Connect the rubber tube to the oil drain port of the caliper, and a small worker keeps stepping on the brake pedal in the car to squeeze out the air in the pipeline until only brake oil is squeezed out.

9. Even if the installation work is completed, it is recommended to step on about 30% of the full force when stepping on the brake every time you go out, so that the oil film on the surface of the brake disc can be worn off slowly, so as to prolong the protection time of the oil film.

|

Material

|

Aluminum |

|

Life time

|

60000-80000kms;

|

|

Certification

|

ISO9001/TS16949

|

|

Package

|

Box+carton+pallet;

|

|

Port

|

Qingdao or others;

|

|

QC

|

1.Sample check;

2.Before production, mould and model check;

3.Technicians self check in production;

4.Engineer spot check;

5.Packing check;

6.Check before shipping.

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!