Product Description

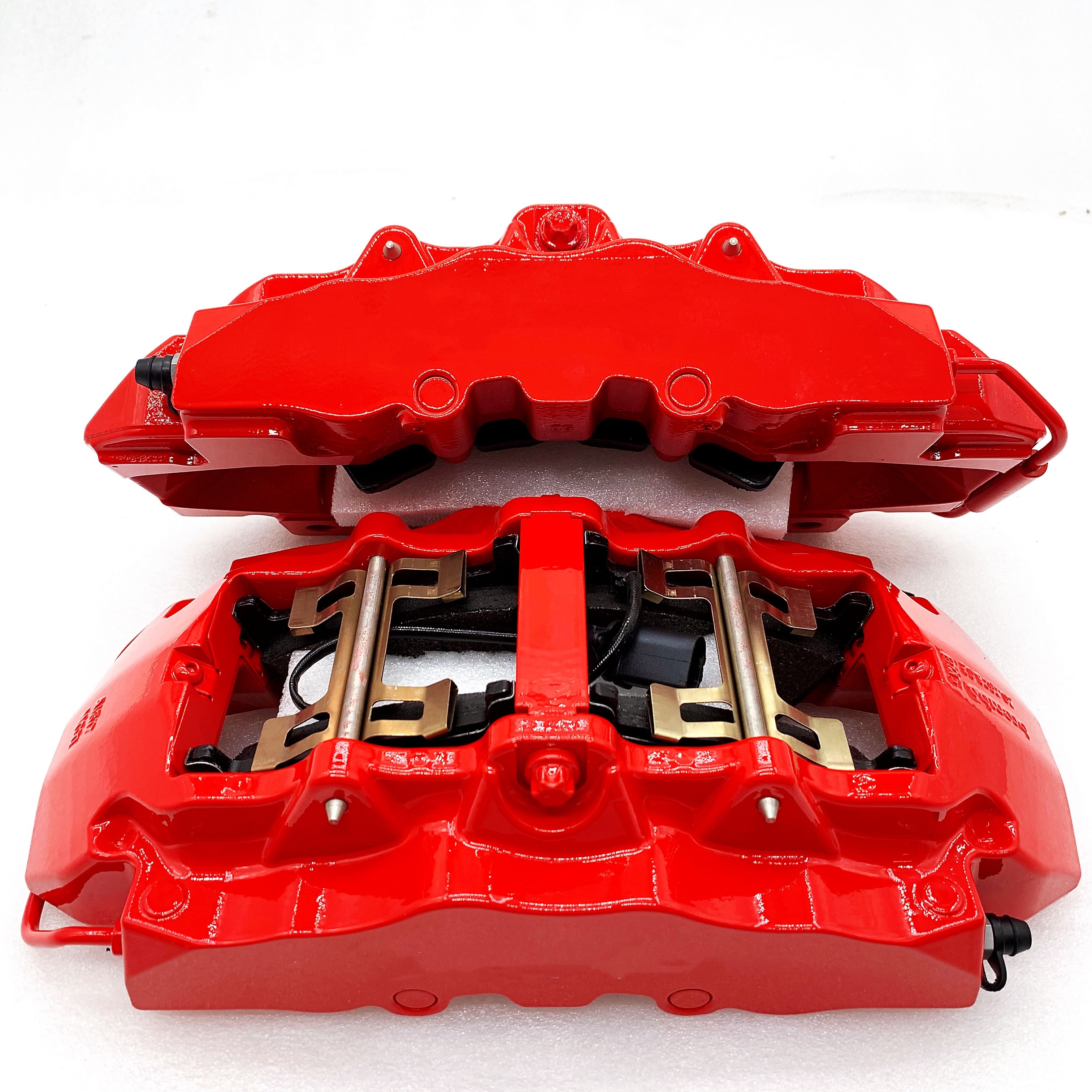

Jekit Car Brake System Iron 355x32mm Rotor Disc Kit 8 Pot Brake

Complete set brake kit included

Caliper, brake disc, brake pad, brake oil, steel throat oil pipe, closure, brake bracket, closure screw, bridge code screw, gasket, sound insulation glue and screw glue.

How to install

Step 1: clean the bearing. After removing the original brake system, clean the bearing part with a steel brush, remove the rust on it, and measure whether the bearing plane is deformed to ensure that the upgraded brake disc fits closely on the bearing.

Step 2: apply sound insulation adhesive to the bearing. Thin application of sound insulation glue on the bearing plane of the original factory can not only prevent the bearing from rusting, but also make the contact between the bearing and the brake disc closer.

Step 3: fix the brake disc. Place the brake disc on the bearing, but note that the screws in this part don't have to be tightened in a hurry. At this step, just fix it.

Step 4: install the axle code and caliper. After the brake disc is fixed, fix the bridge code on the sheep horn, and then fix the caliper on the bracket to ensure the correct installation position of the bridge code, the correct installation direction of the bridge code and the correct installation direction of the caliper. This step is the same. There is no need to tighten the screws in a hurry, just fix them in a fixed position.

Step 5: accurate measurement of caliper position. In fact, this step is often the most easily overlooked, but it is also the most important step in the whole installation process. In the future use of many modified calipers, the uneven strength of left and right calipers, inconsistent wear of brake pads, and even brake jitter are related to this step. This step is to use an accurate vernier caliper to measure whether the caliper and the brake disc are accurately symmetrical up, down, left and right. On the premise of ensuring accuracy, the force pushed out by the piston can be evenly dispersed on the back of the brake pad, completely avoiding the problem of uneven left and right force, resulting in the failure of the caliper to work completely.

Step 6: tighten the screws correctly. After confirming the position of the caliper, the fixed screws need to be coated with screw glue. According to the requirements of the caliper manufacturer, use the correct torque wrench to fix the caliper screws. This is very important. Do not use an air cannon.

If it is found that the upper, lower, left and right positions of the caliper cannot be accurately symmetrical and the error is great, the installation must be abandoned and the supplier is required to re customize the caliper bridge code. Any installation method of modifying the bridge code or using gaskets is unacceptable.

Step 7: install the brake pad + fixed pressing plate. The brake pads of different calipers are installed in different ways, so this step can also be advanced before the calipers are fixed. The more important thing here is to apply sound insulation glue, which can not only make the brake pads work more smoothly, but also reduce the probability of abnormal noise of the brake pads as far as possible. After installing the brake pad, the spring pressing plate at the top shall also be installed.

Step 8: installation of steel throat oil pipe. For refitting brakes, the importance of steel throat need not be said. It should be noted here that the steel throat with appropriate length shall be selected according to different models, and the steel throat with correct interface shall be matched according to the model of caliper.

Step 9: exhaust air from brake oil. This part is very important for the braking system. If the braking system contains air, it will lead to insufficient braking force at light level and loss of braking by directly depressing the pedal at heavy level. Here, I personally suggest using the special equipment for brake oil replacement to directly replace all brake oil. If the brake oil is very new, use the brake oil of the same brand and model to drain the pedal and replenish the oil.

Step 10: check oil leakage + confirm interference. After the air exhaust operation of the brake oil, after a simple test run, stand for 30 minutes, and check whether there is oil leakage at the interface of the brake oil pipe. Once it is found, it must be handled immediately and the air exhaust operation must be carried out again. In addition, after lifting the car, turn the wheels left and right respectively, and observe whether there is any movement interference between brake calipers, bridge codes, screws, oil pipes and other parts, so as to ensure that there is no friction between these key parts and any parts of the body, and the oil pipes are not pulled. Only in this way can we ensure driving safety in the future.

Product Description

| Brand Name |

Jekit |

| Caliper Name |

8 pots Brake |

| Number of pistons |

8 pistons |

| Wheel rim size |

Fit For 18inch wheel |

| Rotor Size |

355*32mm |

Disc Type

|

Holes Disc |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!